Conveyor Belt Motors Conveyor Motor Fluent Conveyors

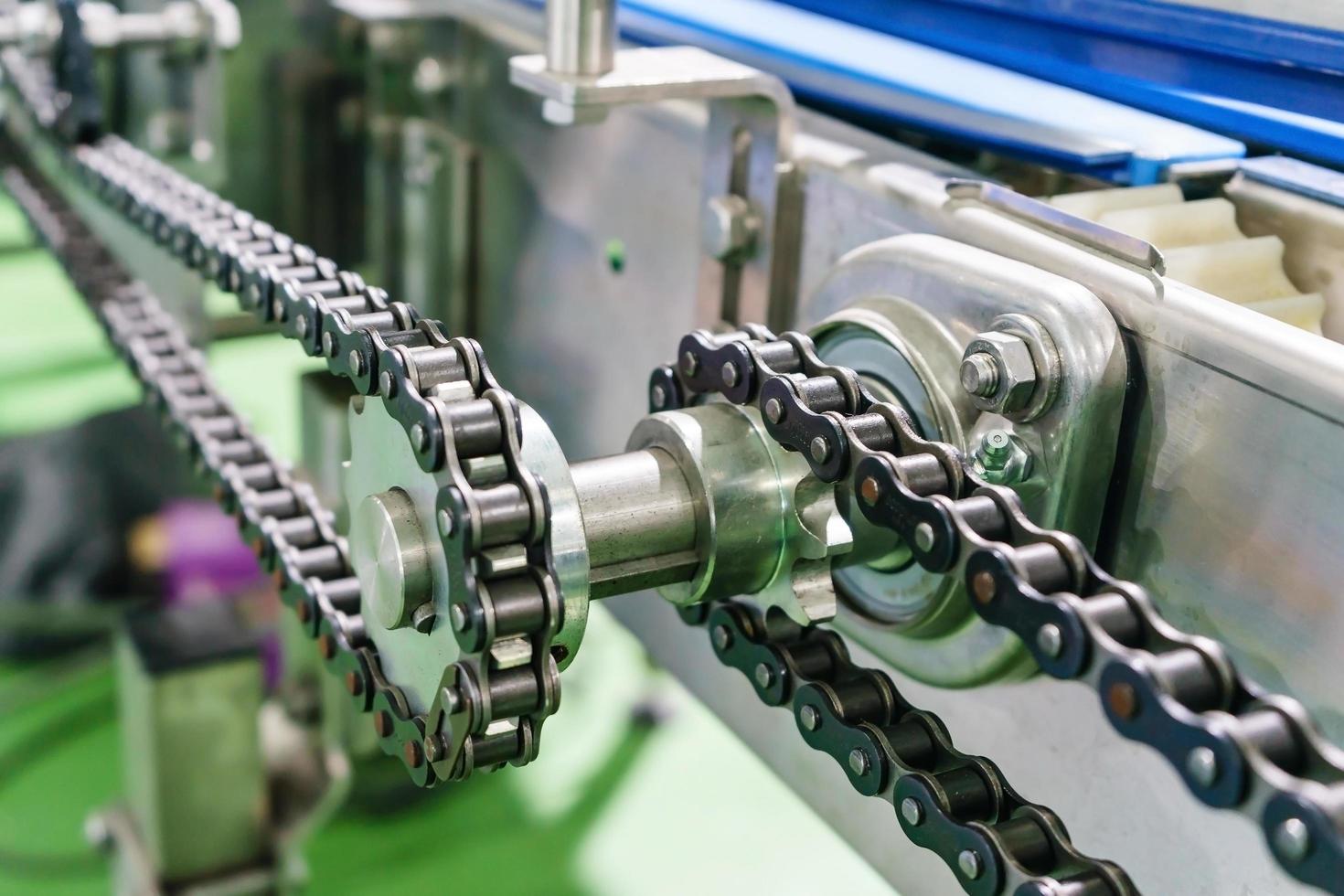

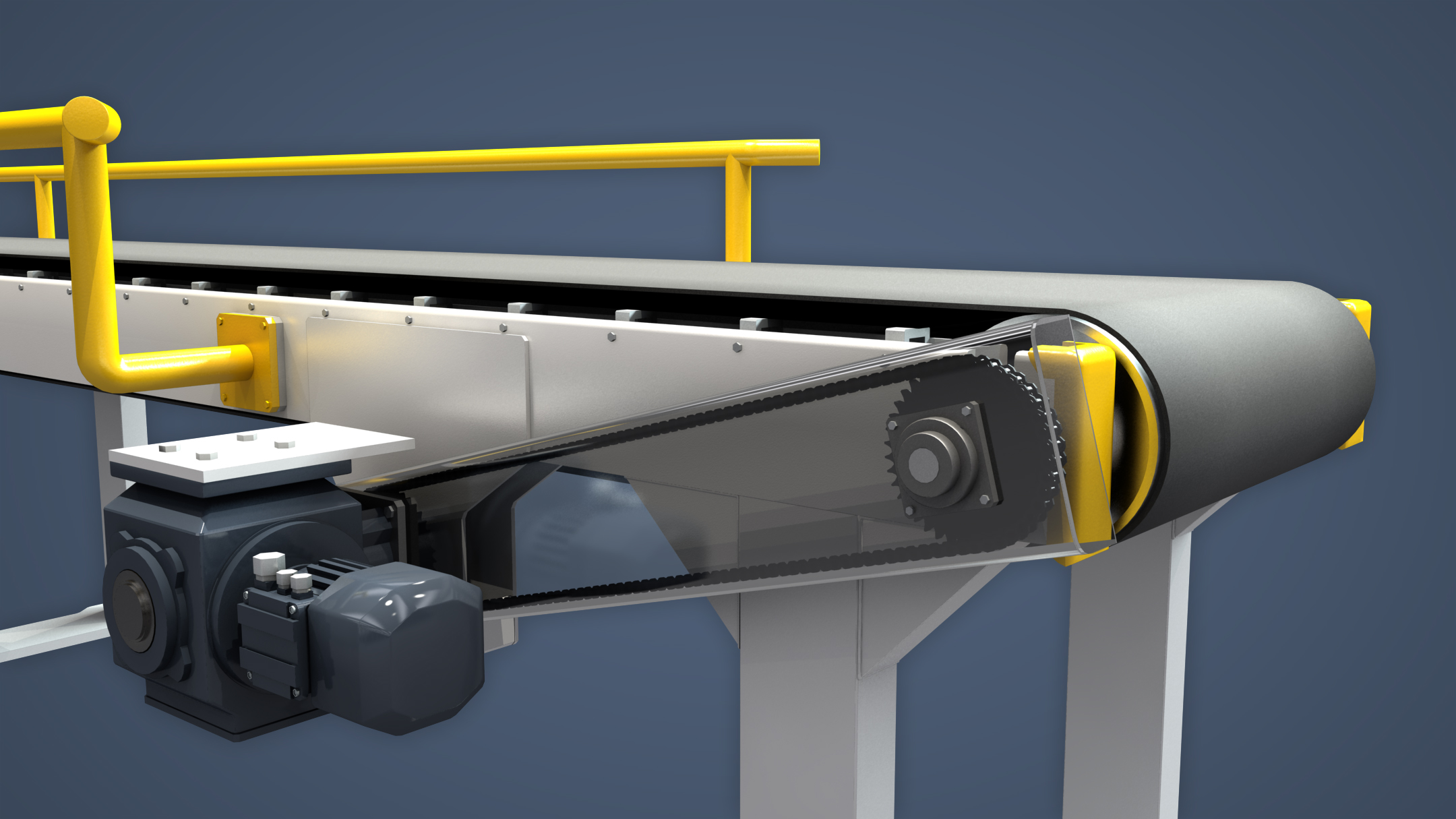

A chain conveyor operates on the principle of interconnectivity: a chain connects each gear, resulting in a smooth conveying process. The chain conveyor has a series of gears connected into a continuous system by the chain.. This leads to a movement of the networked gears and chain to move in the same direction as the motor. As a result, the.

Directdrive motor reduces costs for conveyor setups

precision conveyors used in copying equipment, and the stop-go operation encountered with power and free conveyor chains in transfer lines in the motor industry. Reliable products are identified by their accuracy, close tolerances and proven performance. These are the products that iwis supply. The latest issue of cata-

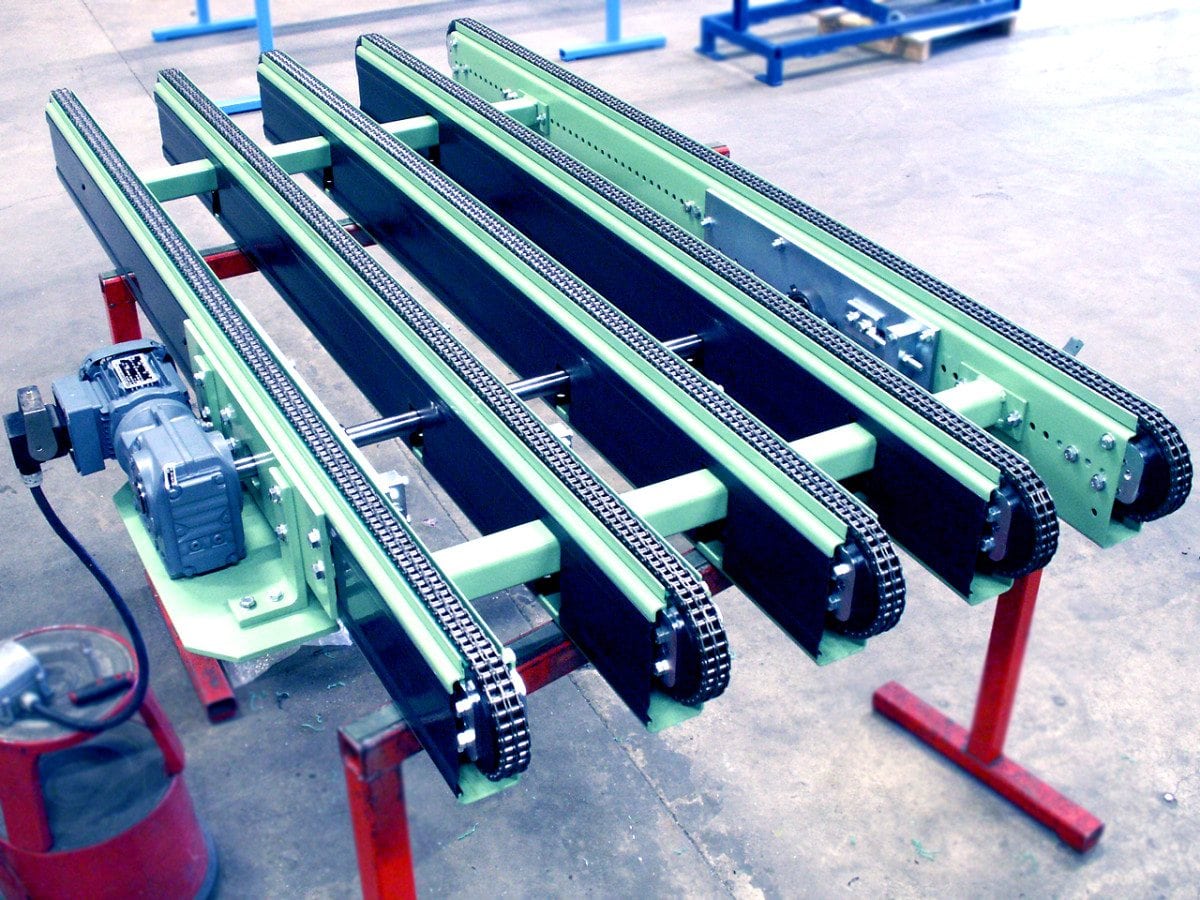

Chain Conveyor Omni Metalcraft Corp.

Once the MAXIMUM CHAIN PULL has been established, the following calculation for head shaft power requirements should be employed. Where: = Torque (Kg m) = Power CV.Hp or KW) = Head Shaft RPM. = total chain pull. = PCD of Drive sprockets (m) From these two relationships it is concluded. From which is derived.

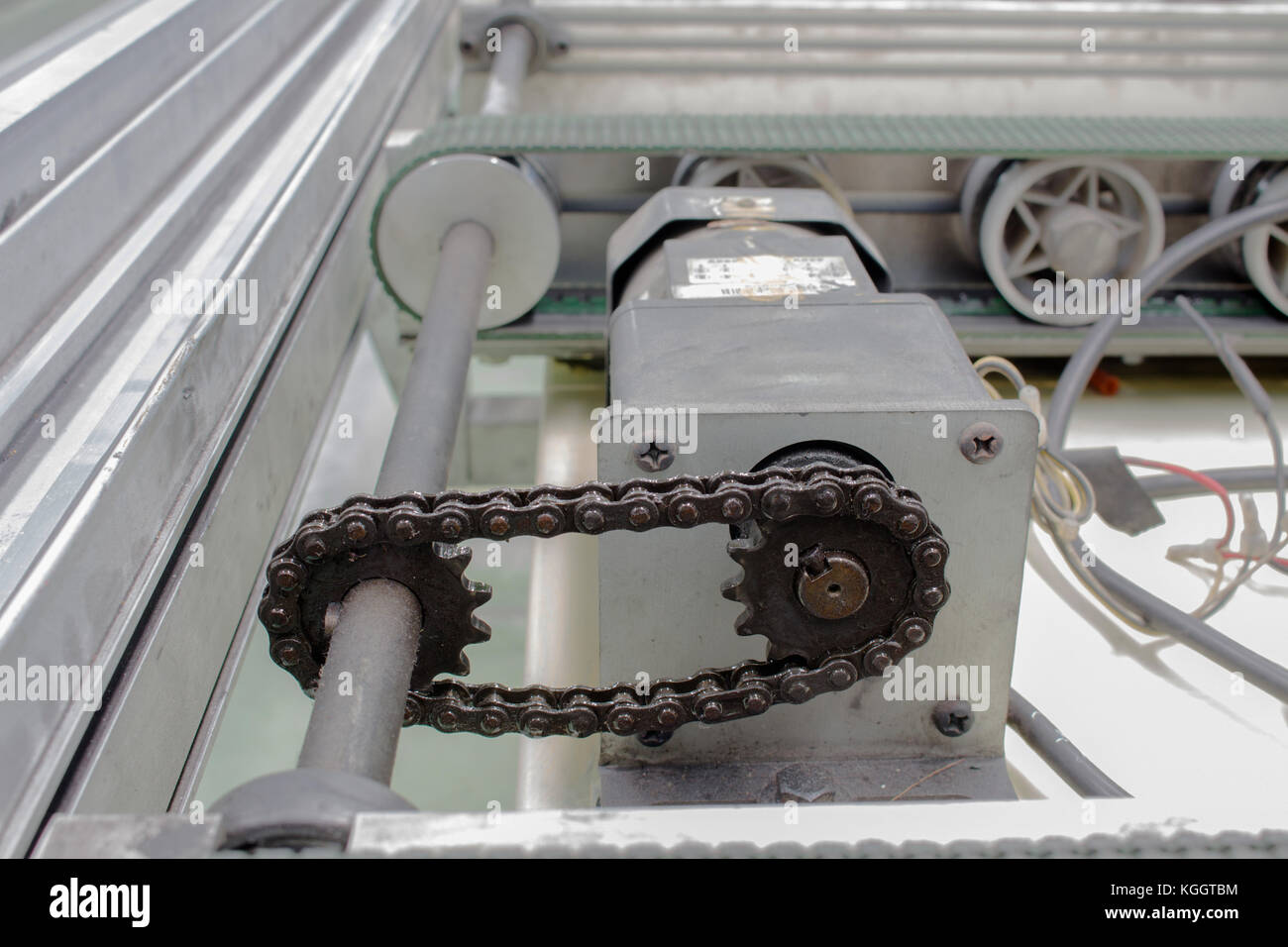

Motor Chain Drive Shaft in Conveyor Line Stock Image Image of steel, machinery 75536019

Sprocket pitch circle diameter: This is the measurement of the diameter about which the chain moves. It is used to calculate a rotational to linear ratio. For our example, 4.01 in. will equate to 12.598 in. of linear travel: 4.01 · π = 12.5977 in. Power-transmission chain mass: The mass of the chain itself is typically included in the load.

Motor drive shaft and transmission chain, conveyor Stock Photo Alamy

Variable Speed Belt Conveyor. The motor sizing results are as follows: We'll need to find a motor that meets these primary requirements. We will skip "Required Stopping Accuracy" and "Other Requirement (s)" for this example. Motor Requirements: Load Inertia = 58,752 oz-in². Required Speed = 19.1~38.2 RPM.

engranaje y eje de transmisión de la cadena en la cadena transportadora, y la cinta

Paella. Arroz a banda: a dish based on rice and fish. Fideuá: a dish based on short pasta and seafood. Olleta de la Plana: a vegetable minestrone. Artichokes of Benicarló filled with shrimps of Vinaroz. Ximo de Castellón: batter filled with tuna, eggs and tomato. Pelotas de fraile: pastry filled with cream. Rosigones: almond biscuits.

PA1500 Chain conveyors » For sideways transportation » MH Modules

Selecting the right chain for a given application is essential to obtain long service life. This guide has been developed for use with Renold conveyor chain to help in specifying the right chain and lubrication for your conveyor system. The significance of the Renold conveyor chain design is emphasised, followed by guidance on selection procedure.

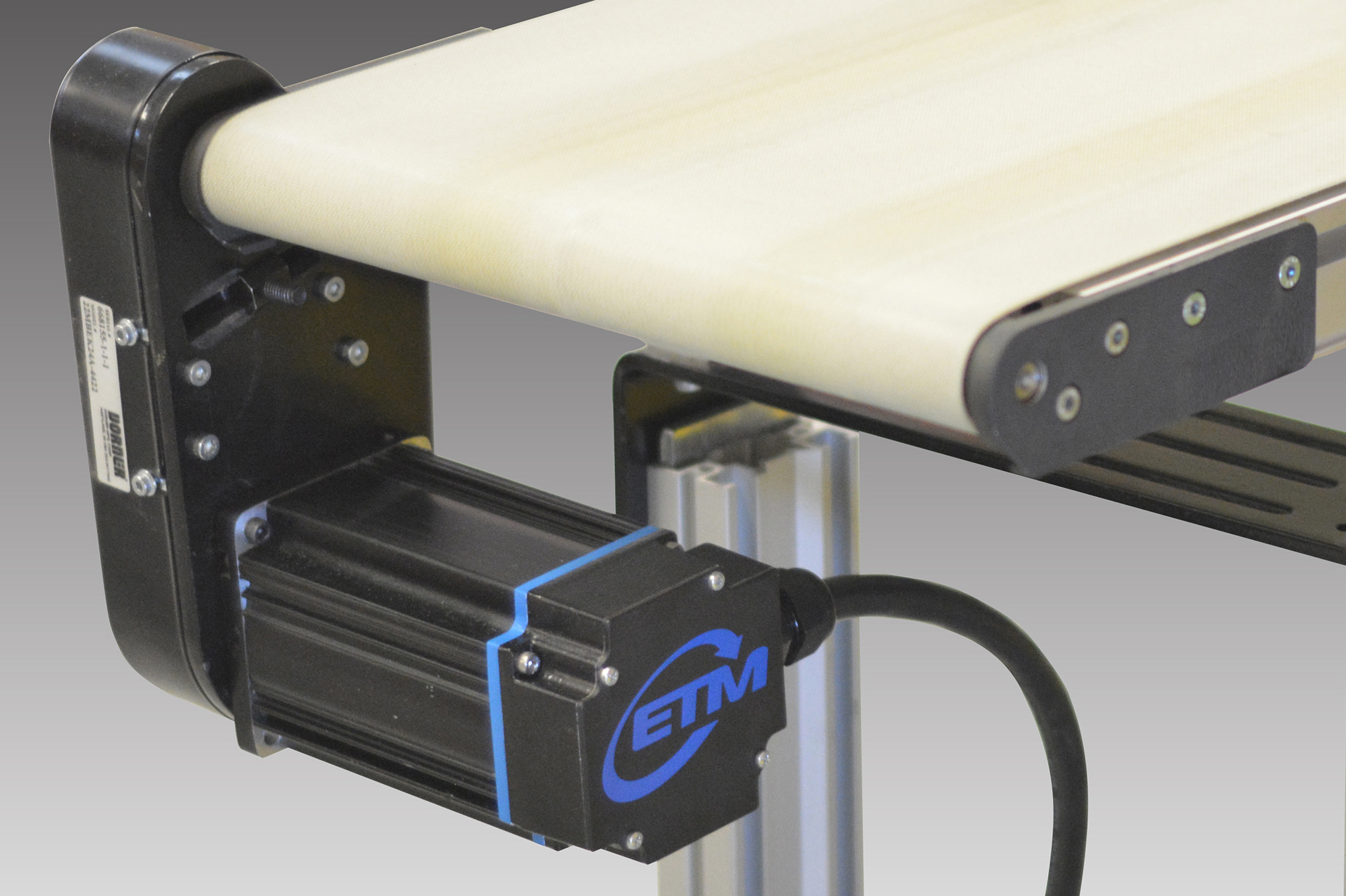

The best motors for conveyors Westeria® Moving Innovation

Idler Wheels for Conveyor Chain Belts. Idler wheels keep the belt moving and prevent sagging. Sprockets for Food Industry Cut-Resistant Conveyor Belting. Choose these sprockets when you need to expand your Ammeraal Beltech MPB conveyor line or replace its worn sprockets. Replacement Belts for

ChainDriven Motors Training Video Convergence eLearning

P = Conveyor chain force to pull the load, kgf; R = Driving sprocket radius, m; F = Pulley peripheral force on driving shaft, m; R1 = Driving pulley radius, m. Calculate the driving chain conveyor power, using the data above. F x R1 = P x R = a) P is the force to carry up the sugar cane plus the chain weight, as we calculated before:

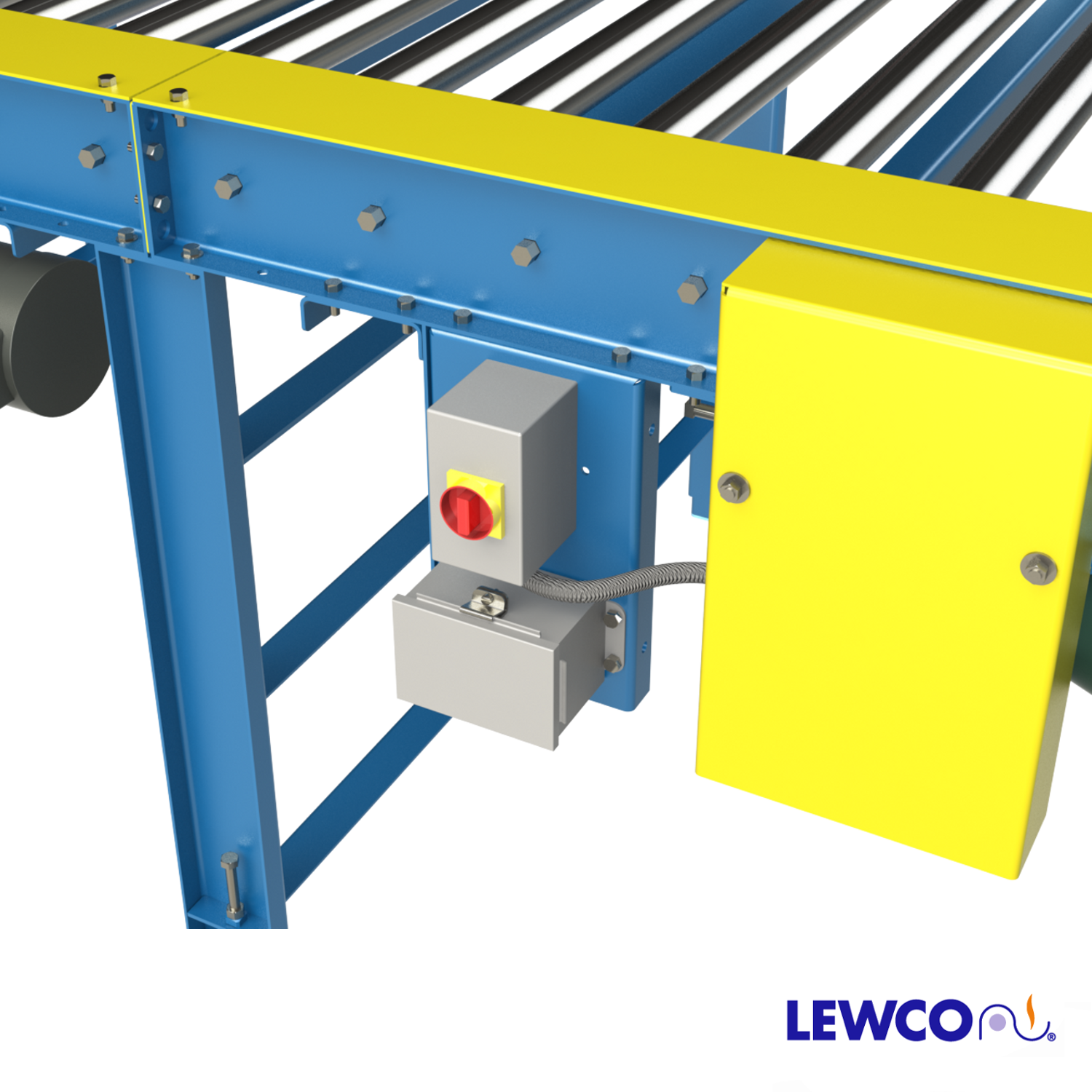

Chain Driven Live Roller Conveyor with Combination Motor Disconnect and Junction Box Mounting

Belt conveyor with a Bodine 42A-FX gearmotor and WPM speed control Industrial automation system with belt conveyor. y APPLICATION NOTE Speed Equation 1: N = (9.55 • V. Equation 2: MOTOR We know that W LOAD = 200 lbs. x 16 oz/lb. = 3,200 oz., V LOAD = 12 in/sec., t a= 1 sec., r = 2 in. and we will assume that J

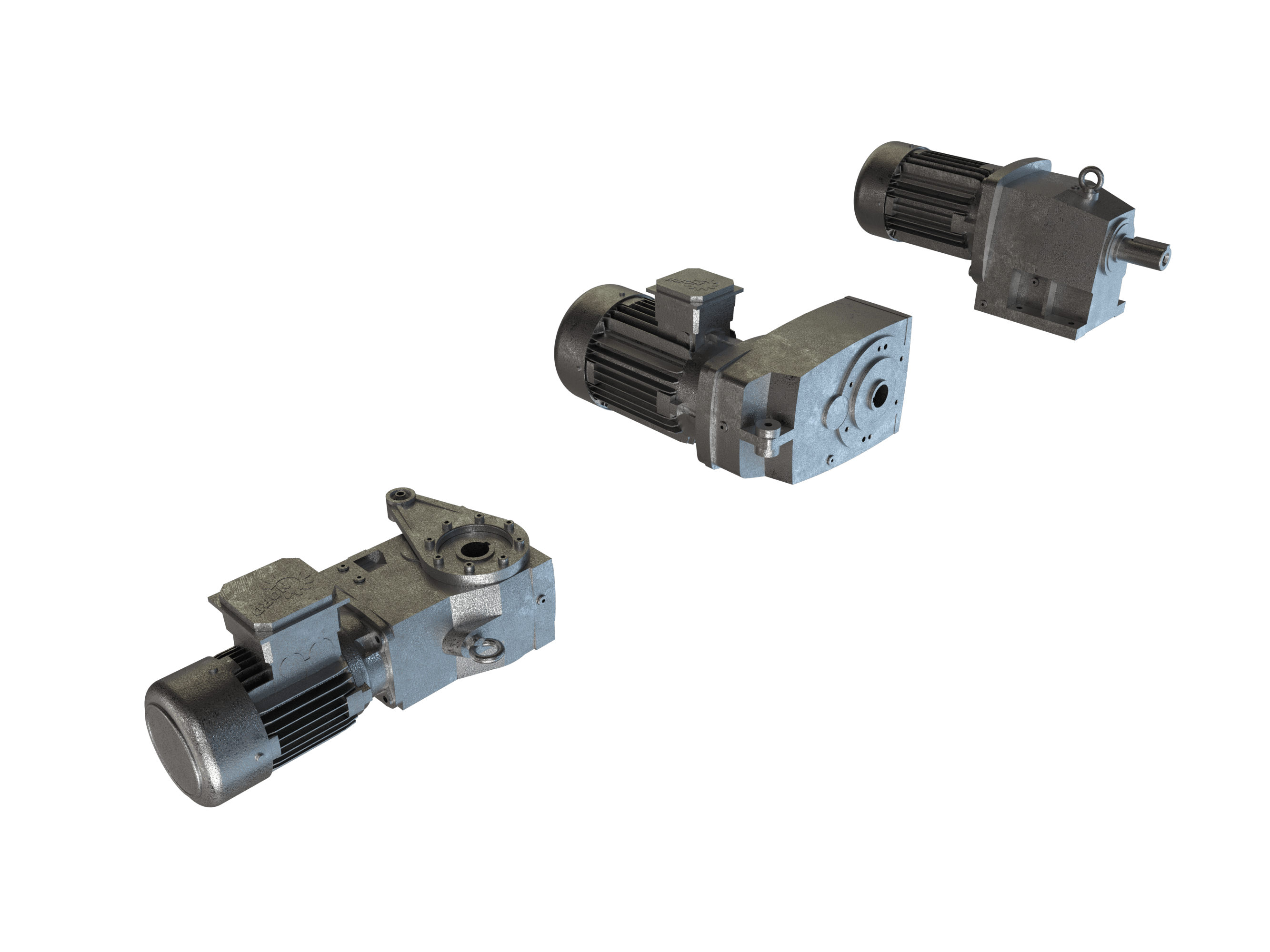

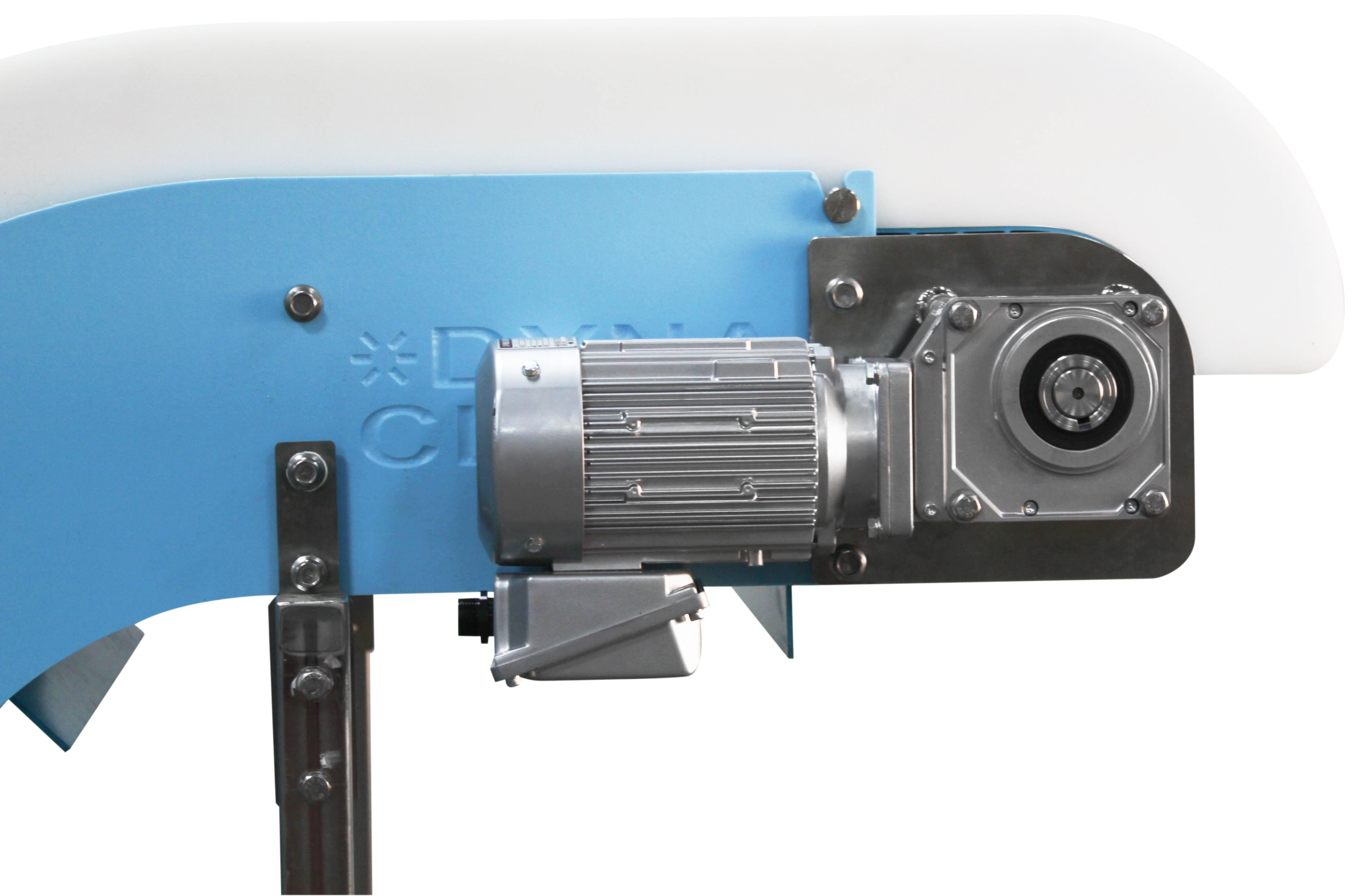

Drive units for chain conveyors modular automation

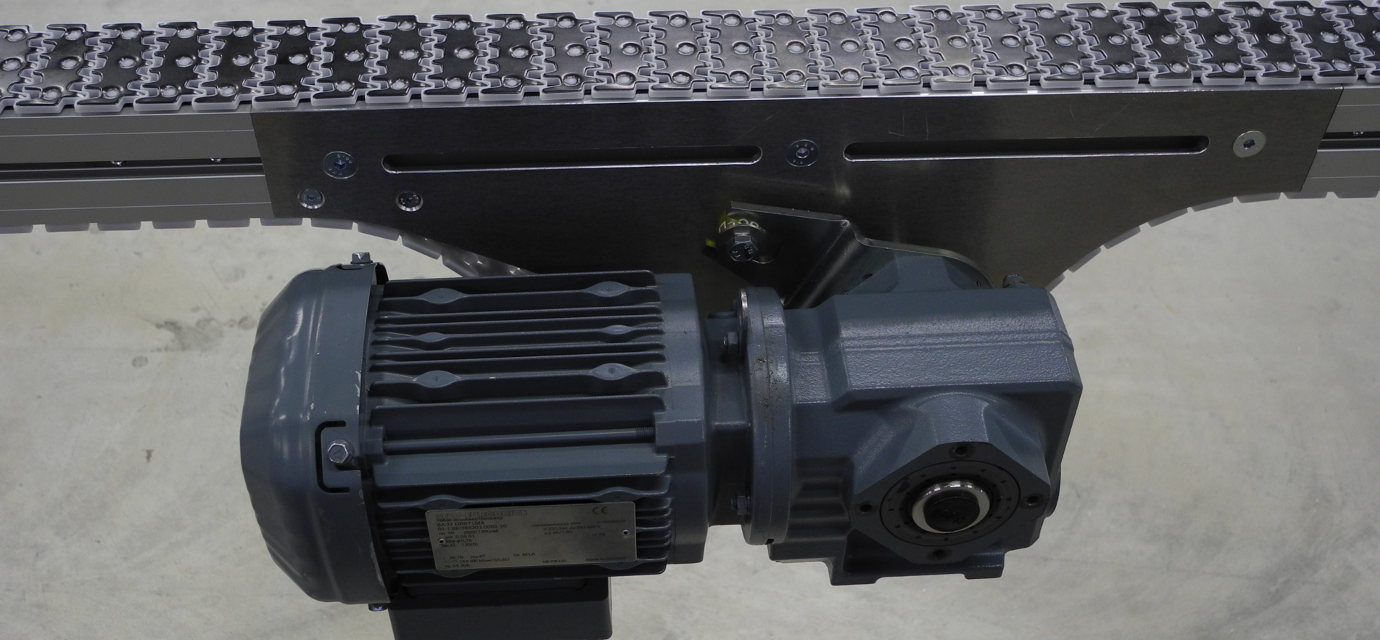

Gearmotor for chain conveyor drive In the case of frequent start-stop operation, consider the load factor listed in a calalog.. Motor speed with commercial power 50Hz 4P:1500r/min 6P:1000r/min 60Hz 4P:1800r/min 6P:1200r/min In the case of inverter drive, the base motor speed is 1800r/min.

Motor Chain Drive Shaft in Conveyor Line Stock Image Image of equipment, detail 69640543

On inclined conveyors the chain will need to be hauled up using a block and tackle, 'Tirfor' or winch (Fig. 1). Care should be taken to make sure that the chain is always restrained and cannot run back. On twin strand conveyors with slats/buckets etc., where access is available at the end of the conveyor, the chain handling lengths can

DynaClean Food Handling Conveyor Accessories Customization Options

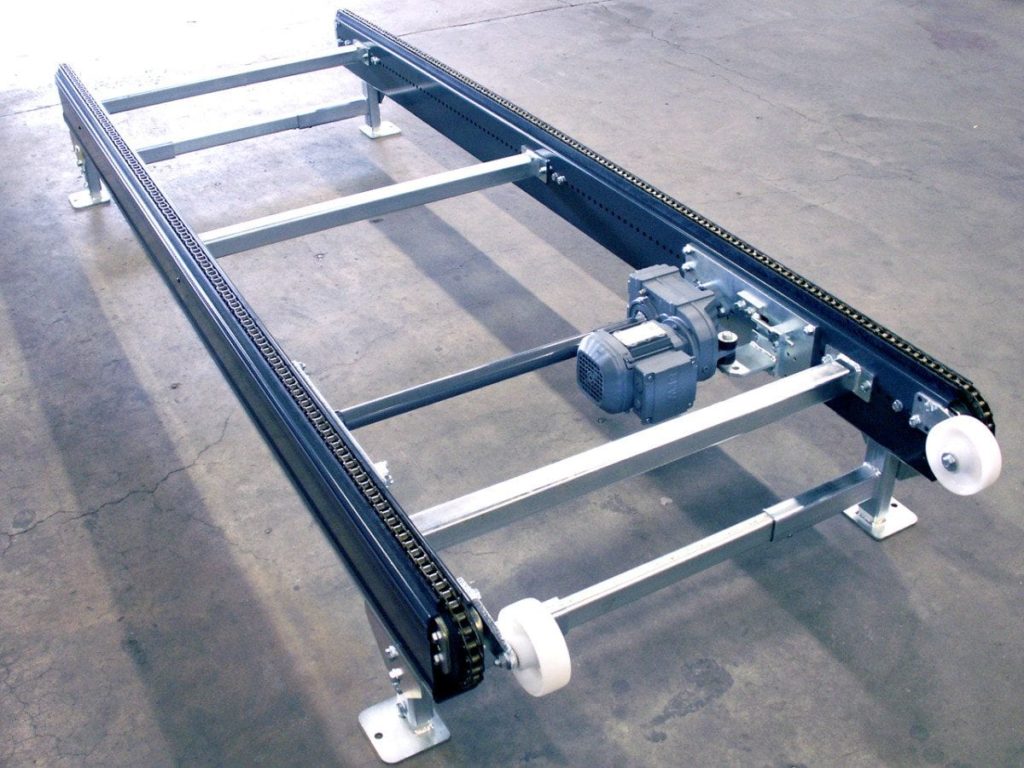

By SEW Eurodrive June 12, 2012. Input data: A chain conveyor is to transport wooden boxes up a slope of α = 5° at a speed of 0.5 m/s. There is a maximum of four boxes each weighing 500 kg on the conveyor. The chain itself has a weight of 300 kg. The friction factor between chain and base is specified at μ = 0.2.

Motor Drive Shaft and Transmission Chain, Conveyor Stock Image Image of power, drive 70191999

Chain conveyors whether known as Drags, Scraper, Paddle, or En-Masse all start out with a continuous chain and fixed flights operating within an enclosed trough. While each individual type functions somewhat differently, their purpose is to accelerate and move a bulk commodity from inlet to discharge at a specific rate. The word "Drag.

Motor drive shaft and transmission chain, conveyor Stock Photo Alamy

The amount of work the motor has to do to drive the chain conveyor, as indicated by the power it consumes, provides extremely valuable insight into the operation of the system - allowing you to take actions that save both time and money. Measuring and monitoring the motor amps should be part of every conveyor operator's maintenance routine.

PA1500 Chain conveyors » For sideways transportation » MH Modules

Chain conveyor systems are ideal for the cycled transport of workpieces or pallets. Available with different drive variants, they are often used to construct complex interlinking solutions. They are typically used for transferring workpiece carriers with high loads and even speeds in a dual line or multiple line configuration. Low-maintenance.