Apa Itu Shell and Tube Heat Exchanger, Bagian dan Cara Kerjanya

A tube and heat exchanger is a device designed to transfer heat from one fluid to another fluid without them touching each other directly. This category of heat exchanger is named after its design, which includes a shell (as a sizable pressure vessel) housing a group of tubes. The tubes are enclosed by another fluid, such as water or air, and.

Mengakses Tubular heat exchanger Teknik Elektro

Silver nanofluids have recently emerged as a promising coolant for enhancing heat transfer performance. This study experimentally investigates the heat transfer characteristics of silver nanofluid in a helical shell and tube heat exchanger. Spherical silver nanoparticles of 143 nm mean diameter were synthesized using a chemical reduction method and characterized comprehensively. The nanofluid.

The Engineering Mindset Shell and Tube Heat Exchanger basics explained

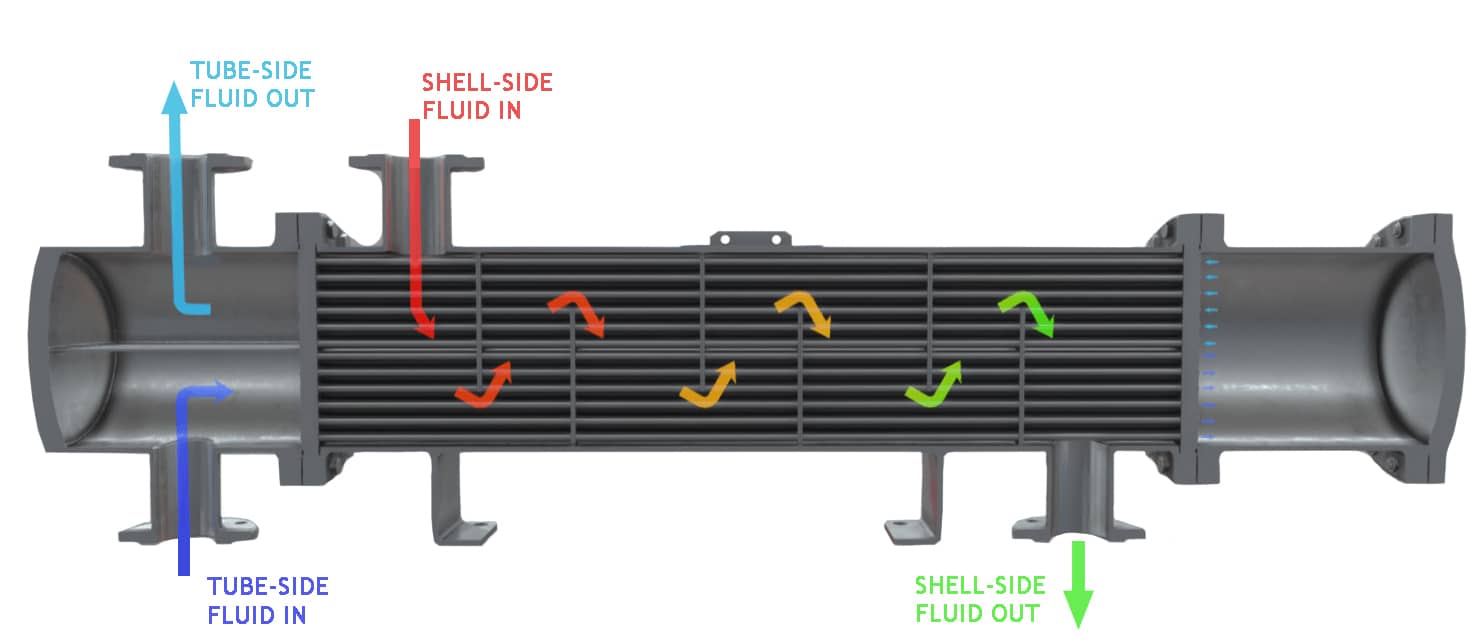

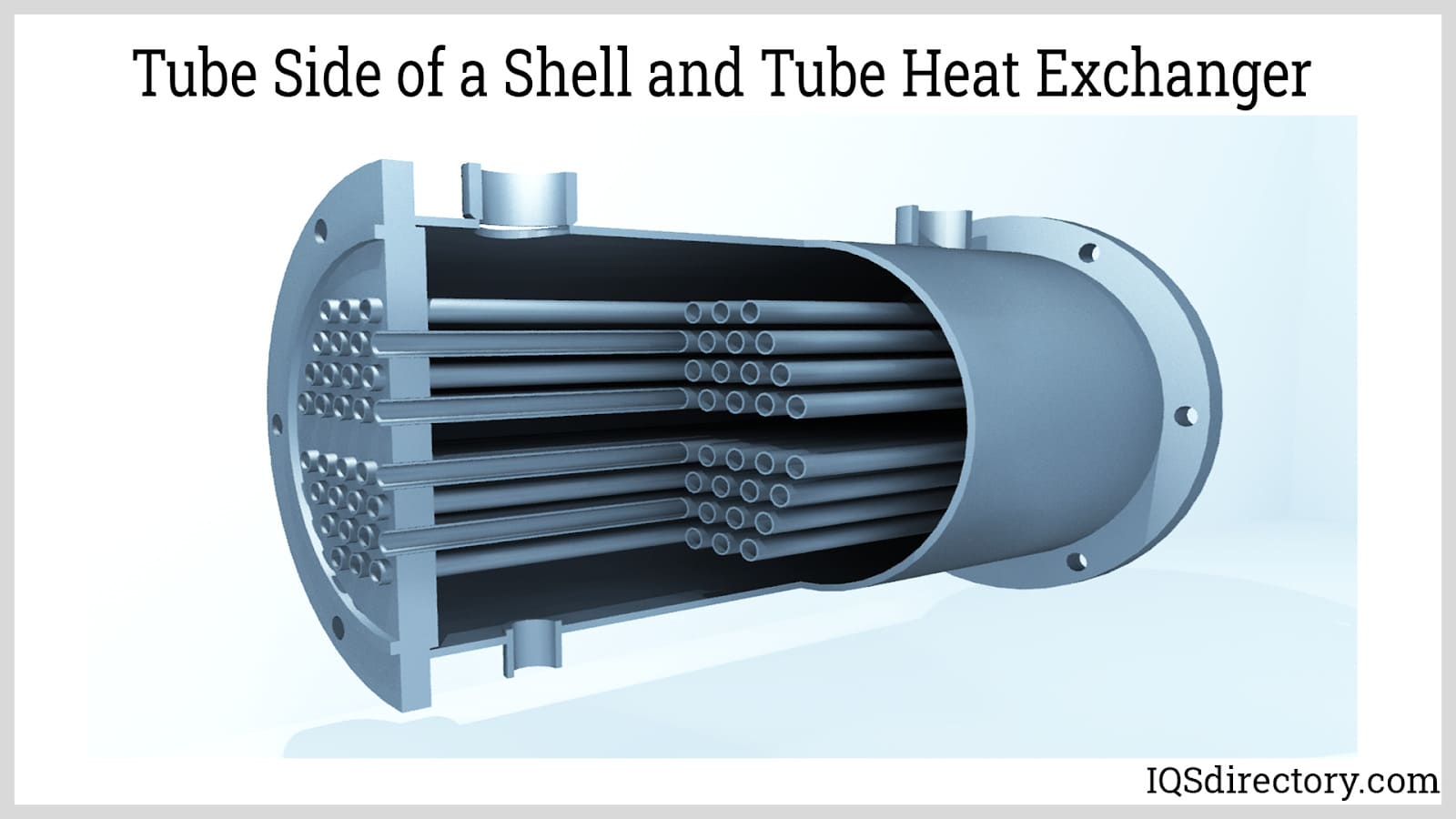

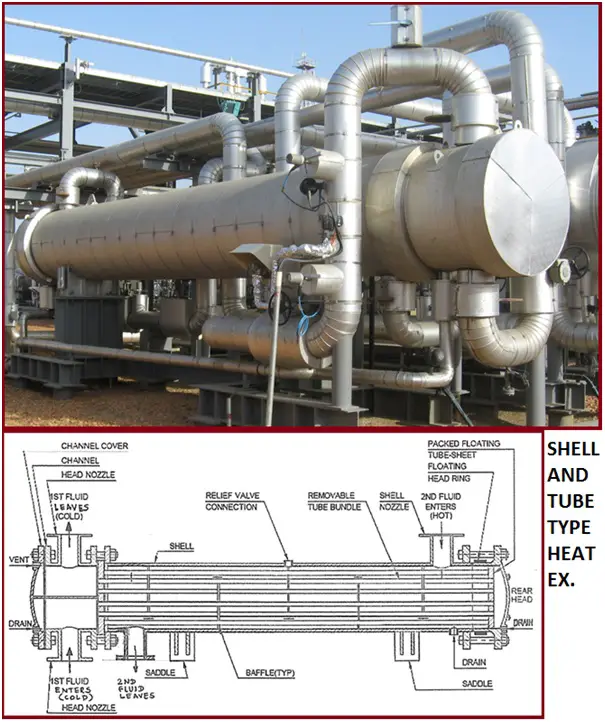

A Shell & Tube heat exchanger is a device in which two fluids, one through the tube side and the other through the shell side, circulating at different temperature conditions, exchange heat through the walls of the tubes, without direct contact between them. These equipment are widely used in chemical process industries, especially in.

Horizontal vs. vertical baffles Which to choose for your shell and

The working of a shell and tube heat exchanger is fairly simple. One fluid flows inside the tubes and the other through the shell. While flowing they exchange heat which means the cold fluid gains the heat from the hot fluid. So one cold fluid enters the shell (or tube side or channel side) inlet nozzle and comes out of the outlet nozzle as hot.

Types of Heat Exchanger according to construction The piping talk

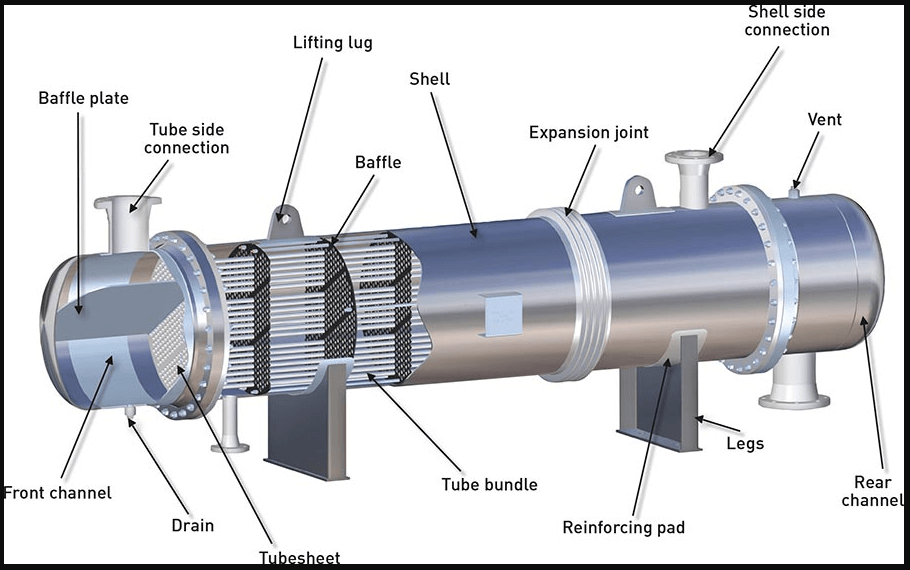

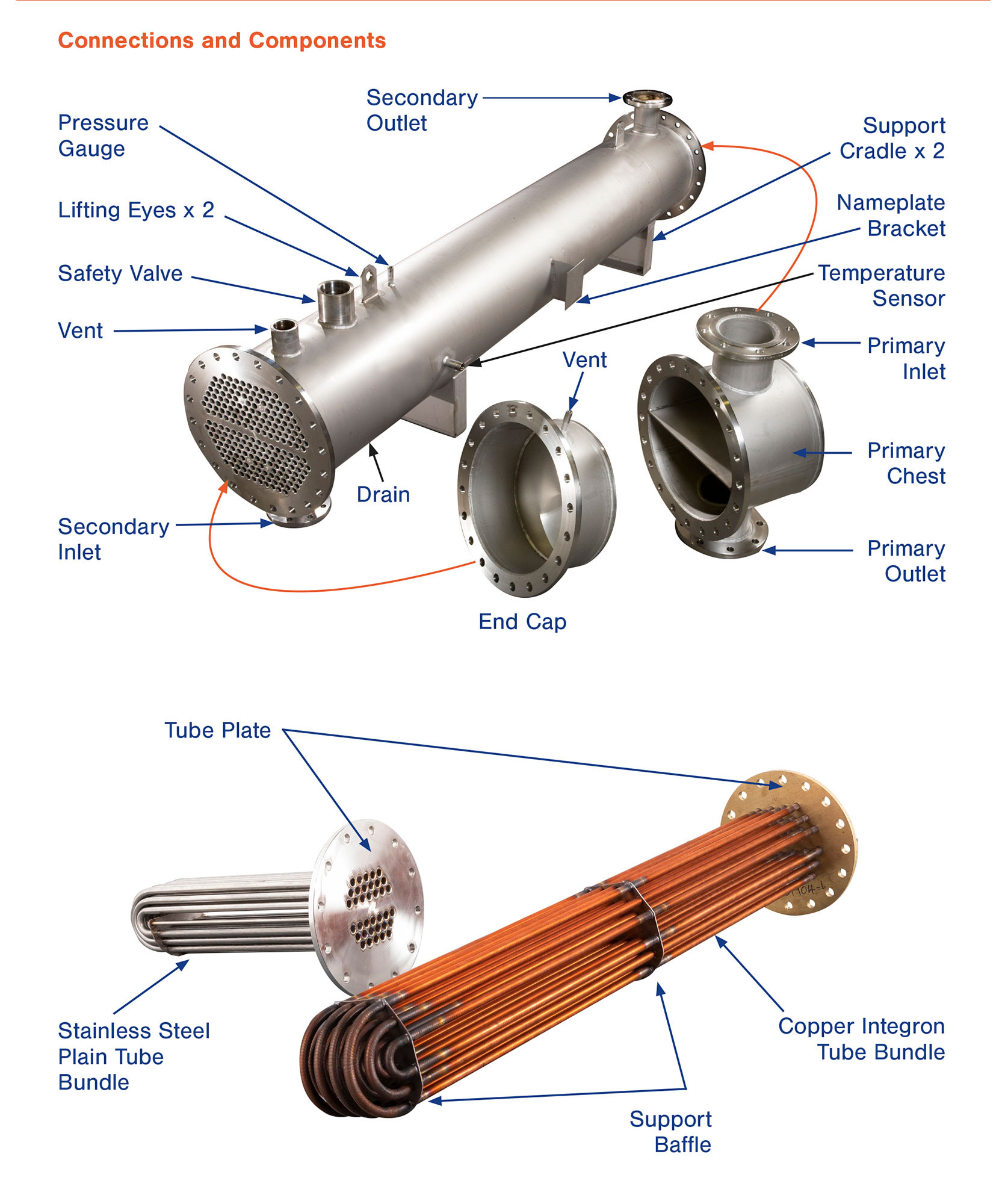

The shell and tube exchanger consists of four major parts: Front Header—this is where the fluid enters the tubeside of the exchanger. It is sometimes referred to as the Stationary Header. Rear Header—this is where the tubeside fluid leaves the exchanger or where it is returned to the front header in exchangers with multiple tubeside passes.

Types of Shell and Tube Heat Exchanger Linquip

A shell and tube heat exchanger, in simple words, is a type of heat exchanger where the two working fluids exchange heat with the help of, as the name suggests, tubes and a shell. One of these is called the tube side fluid and the other is known as the shell side fluid. The tubes are encompassed in a cylindrical shell which exists at a.

Shell and Tube Heat Exchanger Explained saVRee saVRee

Pengertian Shell and Tube Heat Exchanger Shell and Tube Heat Exchanger: Pengantar. Shell and Tube Heat Exchanger adalah sebuah alat yang digunakan untuk mentransfer panas antara dua fluida yang memiliki suhu yang berbeda. Alat ini umumnya digunakan dalam proses industri, seperti pembangkit listrik, pabrik kimia, dan industri petrokimia.

Application of Shell And Tube Heat Exchanger Brise Chemicals

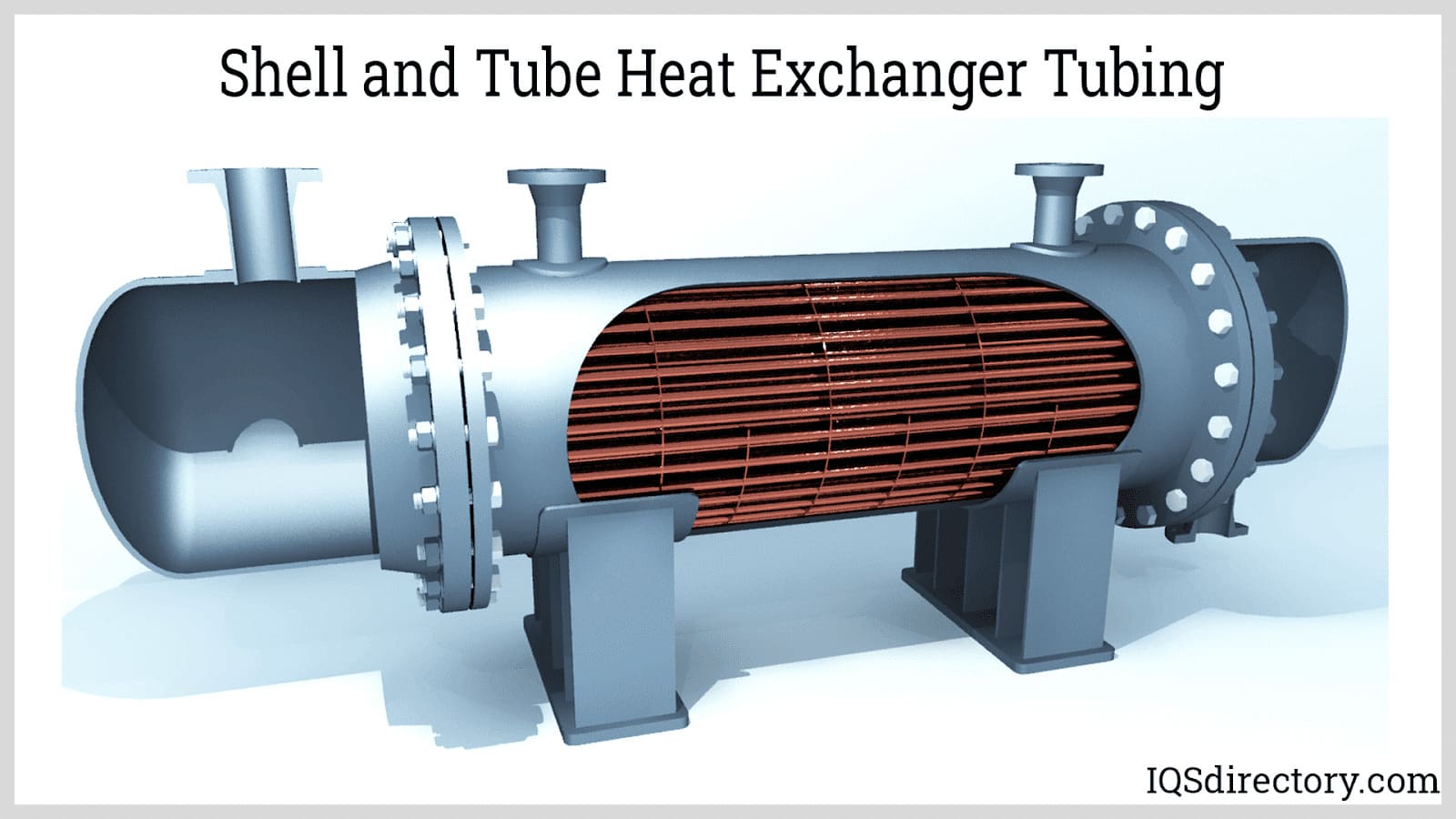

A shell and tube heat exchanger is a mechanical device used for transferring heat between two fluids, typically a hot fluid and a colder fluid while ensuring their separation. The exchanger consists of a cylindrical shell with multiple tubes running through it. One fluid flows through the tubes (tube side), while the other fluid passes through.

Shell and Tube Heat Exchanger What Is It? Types, Process

Chose which fluid is on tube side, which fluid on shell side. Calculate the required duty (Q = m.Cp.ΔT) Calculate the LMTD cc. Calculate the F correction factor. Calculate required UA = Q / (F.LMTDcc) Estimate the overall heat transfer coefficient U. Calculate in consequence the estimated heat exchange area A.

One Pass Shell and Tube Heat Exchanger Explained saVRee

Heat exchangers play a vital role in numerous modern industries. In this study, water and Al2O3 nanofluids were utilized to investigate the thermal efficiency of an industrial heat exchanger, specifically designed with a shell and tube configuration.

Shell & Tube Heat Exchangers for process applications Ormandy Rycroft

Δ = Δ , Δ , is the LMTD for the case of a counter-flow heat exchanger with the same inlet and outlet temperatures. The correction factor, , depends on the geometry of the heat exchanger and the inlet and outlet temperatures of the hot and cold fluid streams. In general ≤ 1, and the limiting value of 1 corresponds to a counter-flow heat.

Shell and Tube Heat Exchanger What Is It? Types, Process

Shell and tube units are a type of heat exchanger commonly used in industrial applications to transfer heat between fluids. The design consists of a shell (outer vessel) and a series of tubes (inner vessel) through which the fluids flow. Heat is transferred between the fluids through the walls of the tubes. Shell and tube heat exchangers are.

Shell and tube heat exchangers Ormandy Rycroft Engineering

Heat Exchanger: Pengertian, Fungsi, Jenis, Prinsip Kerja dan Penerapannya. Heat exchanger, atau bisa disebut sebagai alat penukar panas merupakan alat yang berfungsi untuk memindahkan panas antar 2 fluida dengan suhu yang berbeda. Di antara kedua fluida tersebut ada yang berperan sebagai fluida panas dan juga sebagai fluida dingin.

Shell & Tube Heat Exchanger Piping A brief Presentation

The optimum thermal design of a shell and tube heat exchanger involves the consideration of many interacting design parameters which can be summarized as follows: Process: 1. Process fluid assignments to shell side or tube side. 2. Selection of stream temperature specifications. 3. Setting shell side and tube side pressure drop design limits. 4.

Apa Itu Shell and Tube Heat Exchanger, Bagian dan Cara Kerjanya

Shell and tube heat exchangers are, simply put, a device that puts two working fluids in thermal contact using tubes housed within an outer cylindrical shell. These two integral pathways are usually built out of thermally conductive metals that allow easy heat transfer ( steel, aluminum alloys, etc.). The tubes carry a fluid from their inlet to.

Shell and Tube Heat Exchanger What Is It? Types, Process

A shell and tube heat exchanger consists of a series of tubes housed within a cylindrical container known as a ' shell '. All tubes within the shell are collectively termed a ' tube bundle ' or ' tube nest' ). Each tube passes through a series of baffles and tube sheets (also known as ' tube stacks '). One of the tube sheets is.