Difference Between PVC and Polycarbonate

The acronym PVC refers to the product polyvinyl chloride. Often referred to simply as a "plastic" or even "vinyl", PVC is a man-made thermoplastic material that is utilized in a wide variety of.

Leichte PVCMembranStruktur mit hochfester und Reißkraft

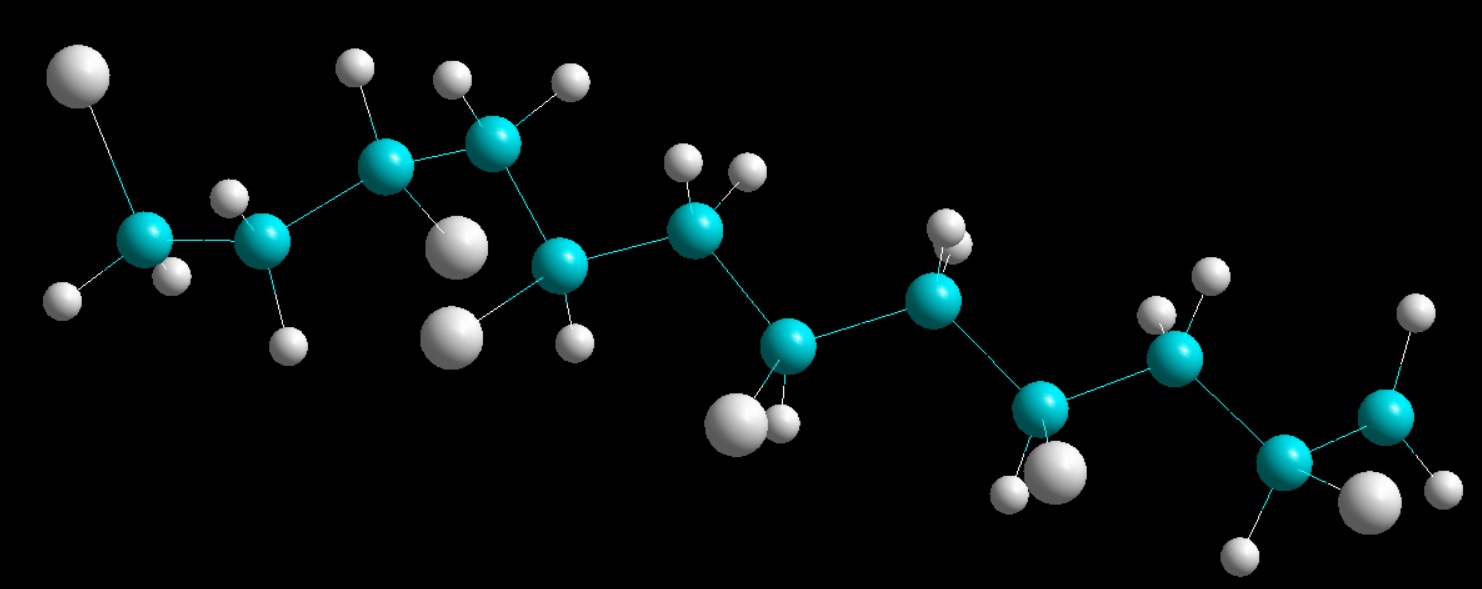

PVC can also be prepared by treating acetylene with hydrochloric acid (HCl) [17]. Its chemical reaction is given below in Fig. 2.3. 2.4 Polymerization Processes PVC can be processed by radical, emulsion, and suspension polymerization. 2.4.1 Radical Polymerization Polymerization of VC occurs via free radical addition process, which comprises

Struktur von Linoleum PVC stockbild. Bild von rückseite 125588353

Struktur polimer PVC cenderung kaku sehingga dikenal memiliki sifat kuat dan kokoh. Oleh karena itu, polimer plastisisasi ditambahkan ke PVC selama proses pembuatan untuk membuatnya lebih fleksibel. Bertentangan dengan uPVC, polimer plastisisasi tidak ada dalam produksi. Akibatnya, uPVC keras dan kurang fleksibel apabila Anda membandingkannya.

Model Plafon PVC Evo Plafon

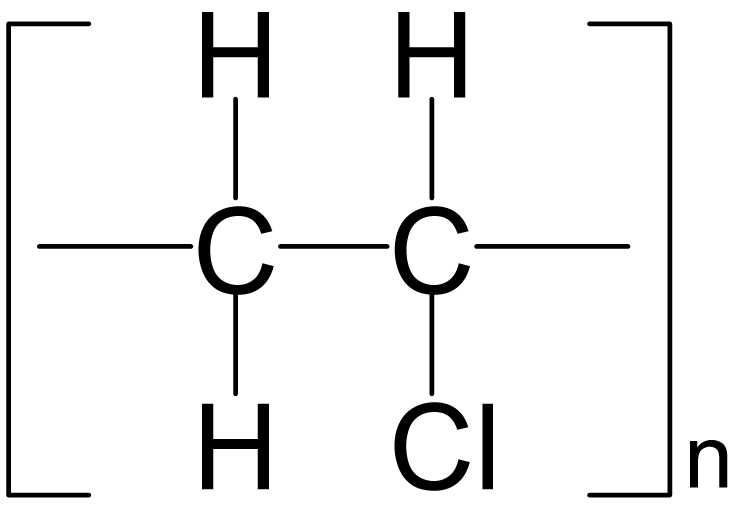

Polivinil klorida. Kecuali dinyatakan lain, data di atas berlaku pada suhu dan tekanan standar (25 °C [77 °F], 100 kPa). Polivinil klorida ( IUPAC: Poli (kloroetanadiol)), biasa disingkat PVC, adalah polimer termoplastik urutan ketiga dalam hal jumlah pemakaian di dunia, setelah polietilena dan polipropilena.

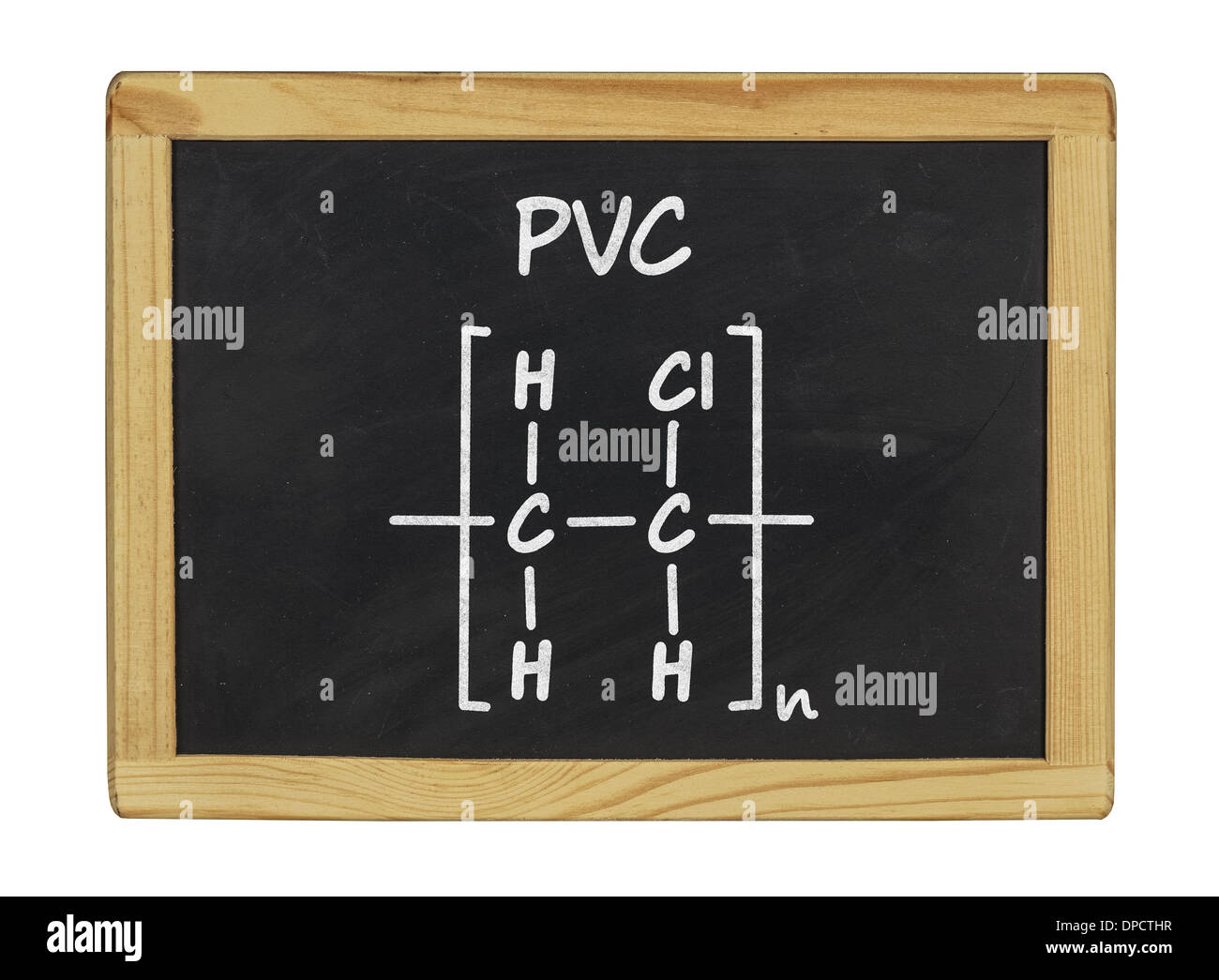

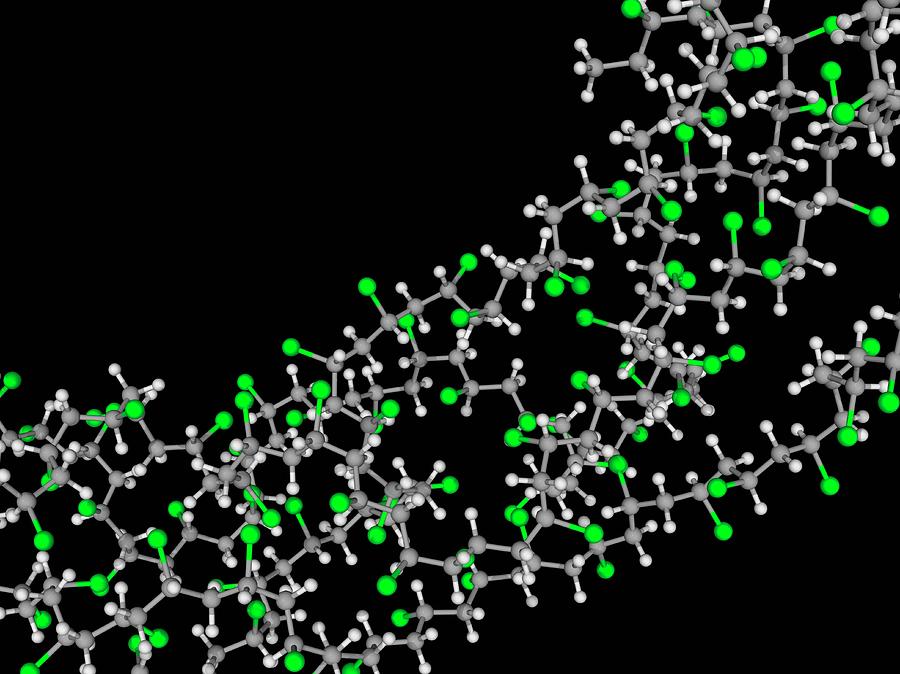

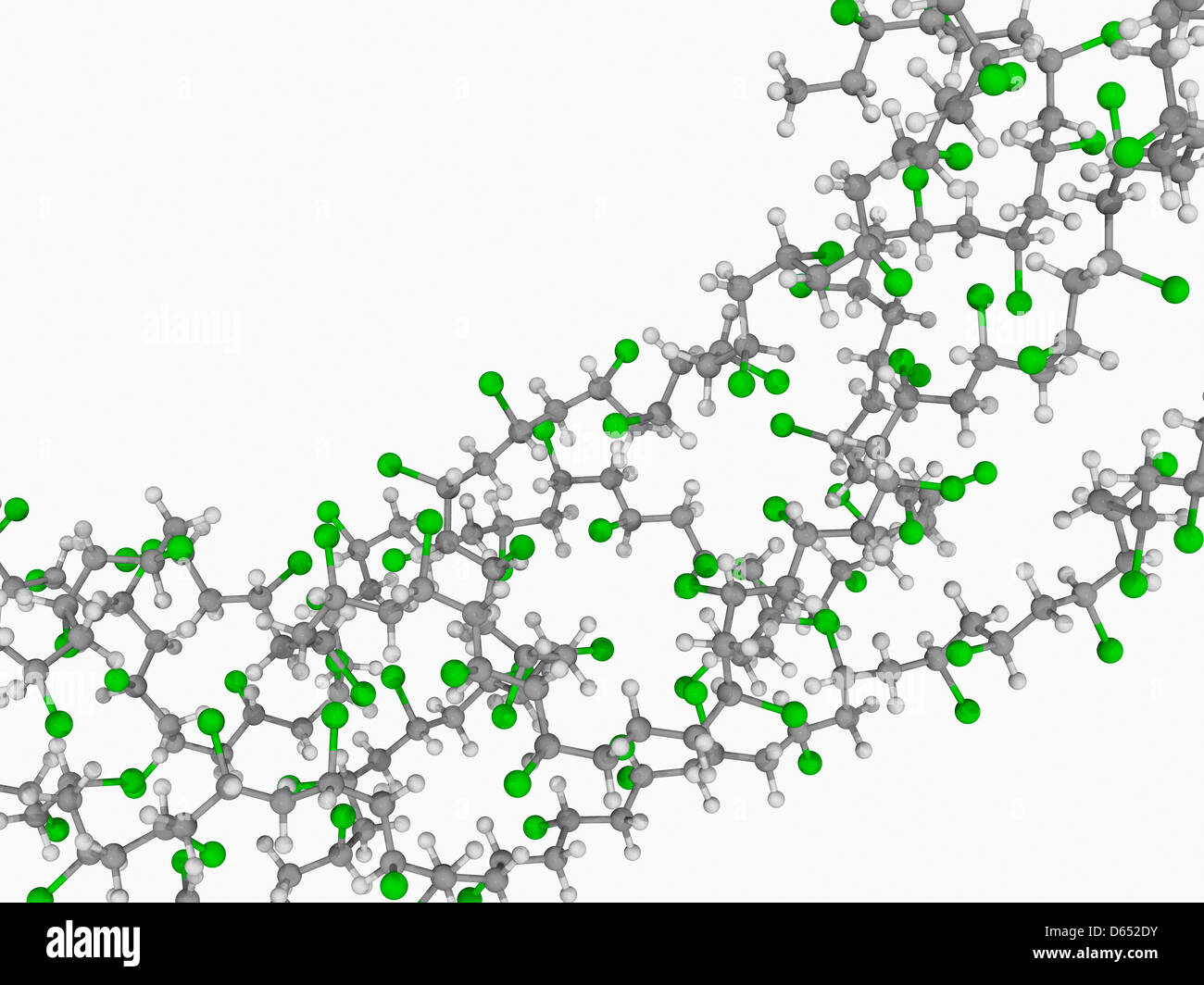

Le poly(chlorure de vinyle) le plastique (PVC), la structure chimique Photo Stock Alamy

Polyvinylchlorid (Kurzzeichen PVC) ist ein thermoplastisches Polymer, das durch Kettenpolymerisation aus dem Monomer Vinylchlorid hergestellt wird. PVC ist nach Polyethylen und Polypropylen das drittwichtigste Polymer für Kunststoffe.. Die PVC-Kunststoffe werden in Hart- und Weich-PVC unterteilt. Hart-PVC wird beispielsweise zur Herstellung von Fensterprofilen, Rohren und Schallplatten verwendet.

Pvc chemische struktur Fotos und Bildmaterial in hoher Auflösung Alamy

It is important to know the polymerization reactivity of VC for synthesizing PVC. Among many vinyl monomers, VC is classified as a non-conjugated weak electron-withdrawing vinyl monomer from the Q- and e-values of VC (0.44 and 0.2, respectively) determined from radical polymerization [16].This indicates that the VC monomer has low reactivity, but its radical is highly reactive.

SinodosChemistry Polymers classification

PVC, in particular regarding the choice of extruder. While the single screw machine dominates in the case of plasticized PVC the twin screw is used in the case of rigid PVC (This is almost the only field where it is used). Figure 3: turbulence mixer. Polyvinyl chloride—Processing and structure 603

Struktur von Linoleum PVC stockbild. Bild von isolierung 125588357

Pembuatan PVC Struktur dan Sifat PVC. mempunyai rumus molekulnya adalah -CH2 - CHCl -n. Bentuk ini mempunyai titik leleh melting point sekitar 204 C dan temperatur transisi glass antara 70 -100 C. Kegunaan dalam kehidupan adalah sebagai pipa plastik paralon, peralatan kelistrikan, dashboard mobil, atap bangunan dan lain-lain .

Gambar Struktur Pvc

Keuntungan dari PVC: PVC adalah bahan murah yang ringan, mudah dibentuk, dan umumnya mudah ditangani dan dipasang. Dibandingkan dengan jenis polimer lainnya , proses pembuatannya tidak terbatas pada penggunaan minyak mentah atau gas alam. (Beberapa berpendapat bahwa ini membuat PVC menjadi "plastik berkelanjutan" karena tidak bergantung pada.

Kunststoffgitter PVC Quadrat Struktur 0,32x185x290 mm (2) 61101 BauerModelle

PVC wall cladding and liner solutions for easy install and maintenance. From hospitals and veterinary clinics to environments such as kitchens, food prep storage, and animal containment, Palram PVC wall cladding and liner solutions hold up where ceramic tiles wont. Give your walls protection against common surface contamination.

Polyvinyl Chloride Pvc Molecule 3 Photograph by Laguna Design/science Photo Library Pixels

PVC is the only general purpose plastic that allows free, wide and seamless adjustment of the required physical properties of products such as flexibility, elasticity, and impact resistance, by adding plasticisers, additives, and modifiers. Since the physical properties of end products are adjustable with additives, only a few types of resin.

Pvc polymer, molecular model hires stock photography and images Alamy

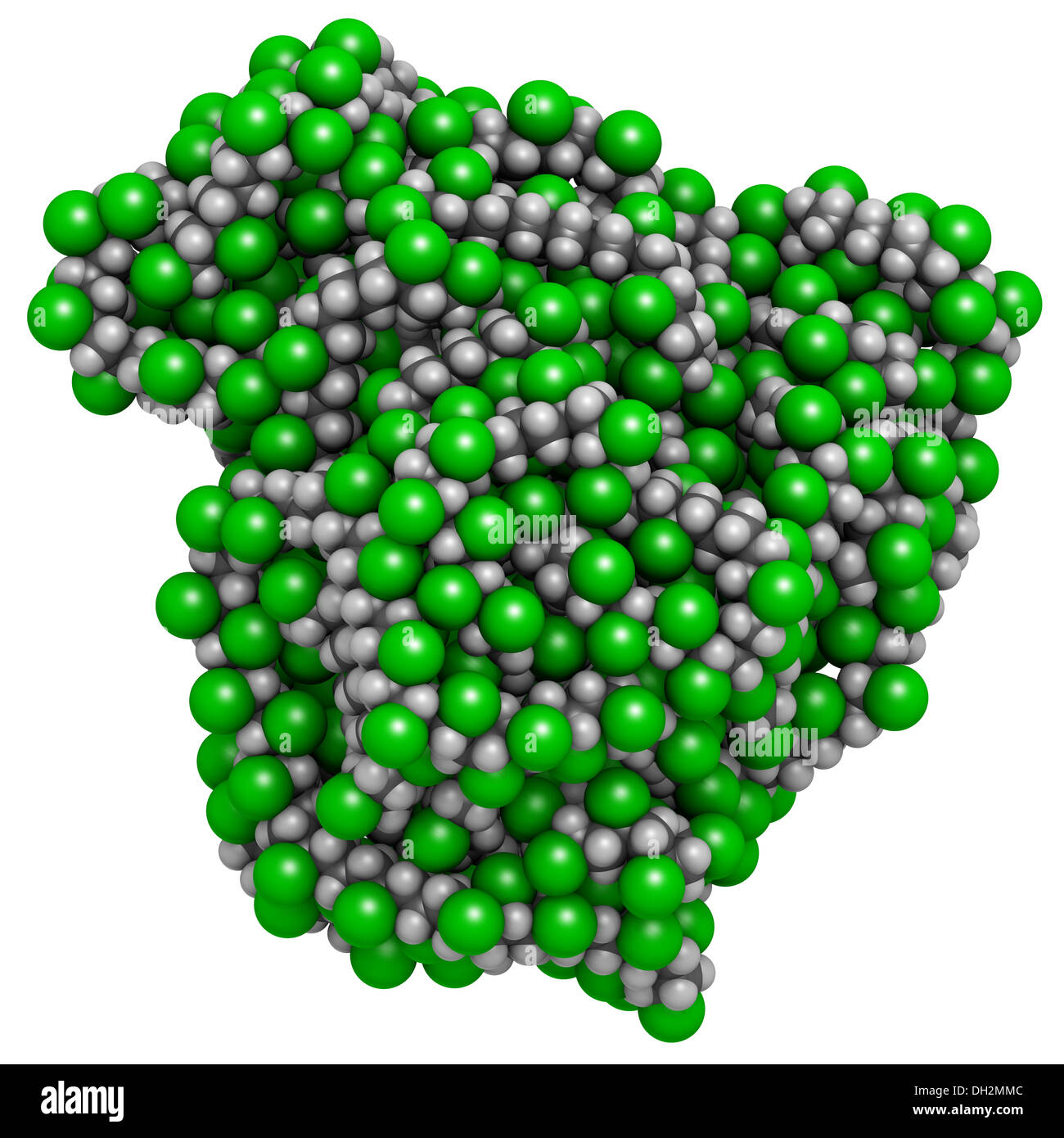

This PVC is used for making pipes, cables, films, floors, paper, coatings, and others. Discover the world's research. 25+ million members; 160+ million publication pages; 2.3+ billion citations;

Struktur von Linoleum PVC stockbild. Bild von rückseite 125588353

PVC coated polyester is known for its excellent strength, flexibility, translucency and affordability compared to PTFE coated glass cloth and ETFE. The PVC coating, which is applied to polyester includes UV stabilizers, fire retardant additives, and anti-fungicides. PVC coated polyester fabrics have a structural lifespan greater than 20 years.

Acylic dehnbares PVCMembranStrukturOberflächenzelt hoch flammhemmend

Dielectric Breakdown Voltage. 40 MV/m. Polyvinyl chloride (alternatively: poly (vinyl chloride), [6] [7] colloquial: polyvinyl, or simply vinyl; [8] abbreviated: PVC) is the world's third-most widely produced synthetic polymer of plastic (after polyethylene and polypropylene ). About 40 million tons of PVC are produced each year.

PVC plastic polymer molecule Stock Image F012/6268 Science Photo Library

The structure of PVC involves a lengthy chain of vinyl chloride molecules, which contain chlorine, hydrogen, and carbon atoms, depicted by the chemical formula C2H3Cl. PVC is a thermoplastic polymer extensively utilized in the construction industry to produce door and window profiles, drinking and wastewater pipes, wire and cable insulation.

What is PVC ? What are the advantages of it as a construction material

Abstract. Polyvinylchloride (PVC) is one of the widely used synthetic polymers which can be used in many industries like packaging, automobiles, electrical, medical, sports and construction. It can be prepared by different polymerization techniques. Multiple additives like lubricants, fillers, processing aids, pigments, blowing agents.