Toleransi ISO ; suaian YouTube

Size limits for Hole Tolerance Classes N3 - N11. Select Units. Millimeters. Inches. Basic Size. Deviation in microns. Green = "Prefered" tolerance classes. Find your data faster with our Fits and Tolerance Calculator. Basic Size.

Calaméo tableau ecarts arbre alesage tolerance iso

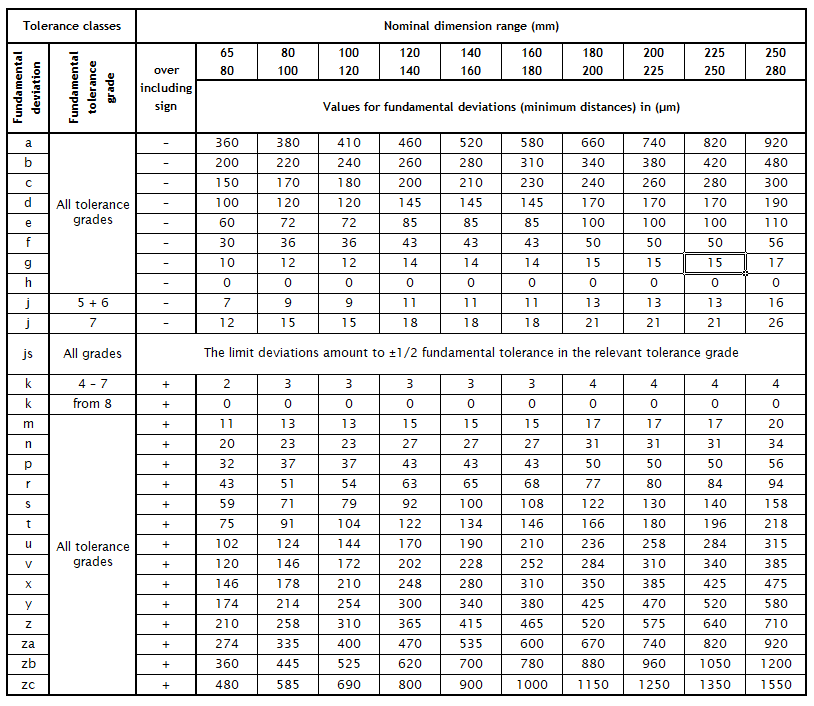

shaft tolerance table (iso) ≥ < b10 c9 d8 e7 e8 f7 g7 h6 h7 h8 js7 k7 m7 n7 p7 r7 s7 t7 - 3 +180 +140 +85 +60 +34 +20 +24 +14 +28 +14 +16 +6 +12 +2 +6 0 +10 0 +14 0 ±5 -10-2-12-4-14-6-16-10-20-14-24-3 6 +188 +140 +100 +70 +48 +30 +32 +20 +38 +20 +22 +10 +16 +4 +8 0 +12 0 +18 0 ±6 +3-9 -12-4-16-8-20-11-23-15-27-6 10

Exemples d´utilisation du système ISO de tolérances

INTERNATIONAL STANDARD. ISO 13920:2023(E) Welding — General tolerances for welded constructions — Dimensions for lengths and angles, shape and position. 1 Scope main document specifies general criterion of to structures election of in particular tolerances tolerance on customary on dimensions the functional workshop requirements individual.

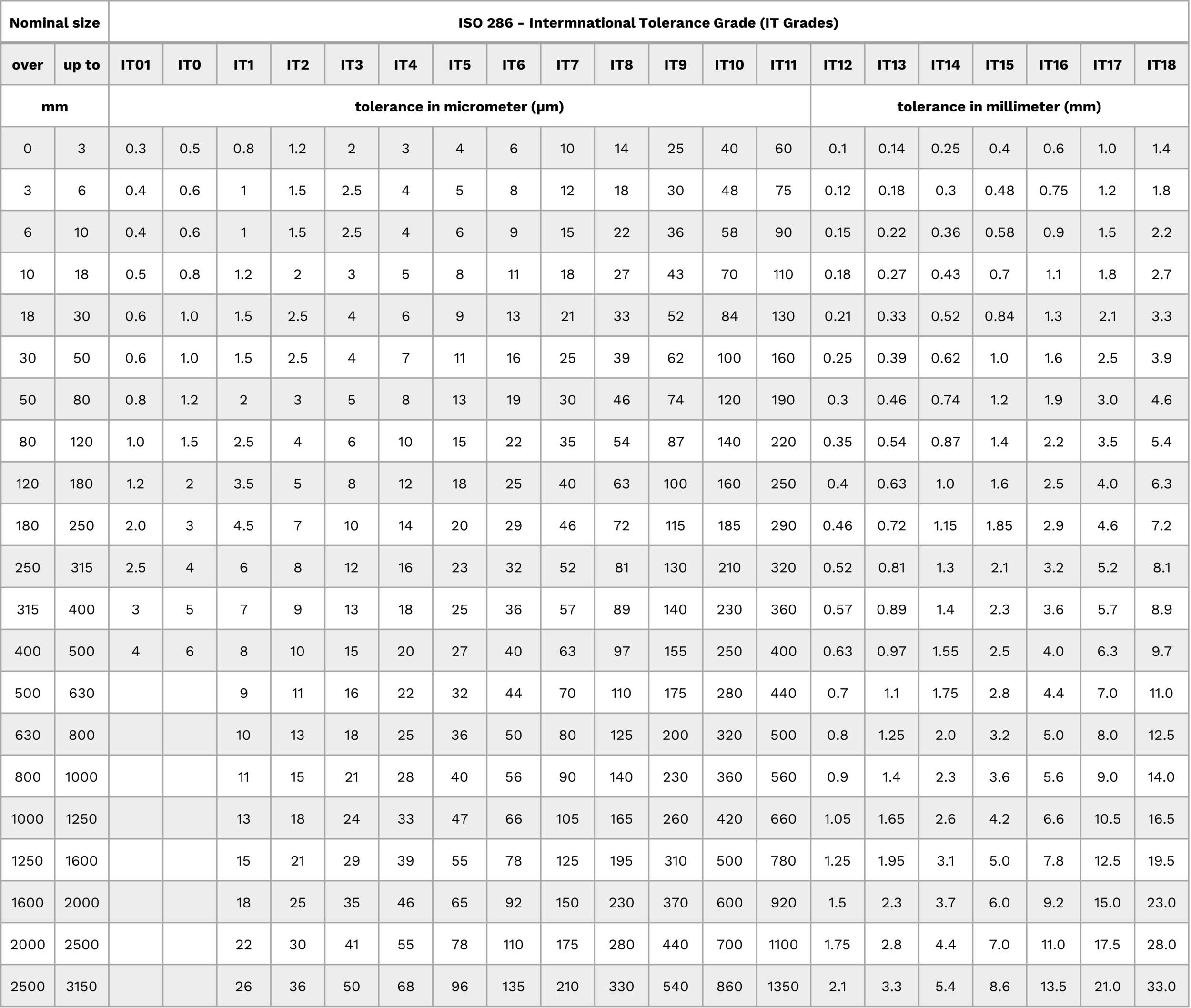

How to apply General Tolerance Steps to be followed in ISO 286 standard chart YouTube

Part 1: General Tolerances ISO 2768-1. ISO 2768-1 is intended to simplify drawing indications and specifies general tolerances in 4 tolerance classes (f - fine, m - medium, c - coarse, v - very coarse). It applies for the linear dimensions and angular dimensions such as external sizes, internal sizes, step sizes, diameters, radii.

Tabel Toleransi Iso

1 Scope. This part of ISO 2768 is intended to simplify drawing indica tions and it specifies general tolerances for linear and angular dimensions without individual tolerance indications in four tol erance classes. NOTE 1 - The concepts behind the general tolerancing of linear and angular dimensions are described in annex A.

Iso 2768 Hole Tolerance Table

3- Special case for M6 from 250mm to 315mm tolerance. 4- Some internal Grade values must be rounded down to a precision of 3 decimal metric millimeter precision. Select between millimeters and inches the unit of measure the results will be displayed. All internal calculations are done using metric millimeters.

Iso 2768 M Tolerances moviepsawe

Our Fits & Tolerances Calculator allows you to easily determine type of fits using the tolerances according to DIN ISO 286. In addition, upon entering the nominal diameter the tool calculates lower and upper limit deviations plus the maximum and minimum interferences dependent on the selected tolerance classes for bore and shaft. ISO Fits.

Shaft Tolerances and fits ISO fundamental deviations for external dimensions Engineersfield

ISO 2768-mK means the dimension information for which the tolerances are not specified will be followed according to the m and K class. m class is specified in ISO 2768-1, and the K class is specified in ISO 2768-2, which includes H, K, and L tolerance levels. The following is a summary of ISO 2768-1 and ISO 2768-2 specifications:

MEMAHAMI TOLERANSI Bagian 1 Inovator Teknik

ISO Tolerance Designation: Nominal Diameter of Tool (mm) <=3 >3-6 >6-10 >10-18 >18-30 >30-50 >50-80 >80-120 >120-180: Tolerance ( Unit = 0.001 mm ) d9-20 -45

ISO Hole Tolerance Chart

ISO 2768-1 is intended to simplify drawing indications and specifies general tolerances in 4 tolerance classes (f - fine, m - medium, c - coarse, v - very coarse). It applies for the linear dimensions and angular dimensions such as external sizes, internal sizes, step sizes, diameters, radii, distances, external radii, and chamfer.

Iso 2768 Hole Tolerances

Therefore engineers define general tolerances in engineering drawings to define the variation. ISO 2768 standard defines general tolerance for: Linear Dimensions. Angular Dimension. External Radius and Chamfer height. Geometric tolerance such as straightness, flatness, perpendicularity, symmetry, and runout. We suggest you read this article on.

engineering tools Toleransi Bentuk Dan Posisi *Gambaran Umum Metrologi Pengukuran

Tolerance according to ISO 22081. As a designer, ISO 22081 enables you to optimally simplify product specifications and proof of conformity and to fully describe all non-functional characteristics, taking into account production-related and material-physical characteristics. Careful application of the general tolerances can help to simplify the design process and ensure that the results meet.

ISO Tolerances For Holes PDF Engineering Tolerance World Economy

Fits and tolerance calculator for shaft and hole tolerance calculation according to ISO 286-1 and ANSI B4.2 metric standards . The schematic representation of the fit is also drawn by tolerance calculator. The tolerances defined in ISO 286-1 are applicable to size range from 0 mm to 3150 mm but there are exceptional cases defined in the.

Iso Standard Metric Thread Chart Pdf

ISO 2768 is mainly for parts that are manufactured by way of machining or removal of materials. Linear Dimensions: Permissible deviations in mm for ranges in nominal lengths: f (fine) Tolerance class designation (description) v (very coarse) m (medium) c (coarse) 0.5 up to 3 : ±0.05 : ±0.1 : ±0.2 -over 3 up to 6 : ±0.05 :

ISO 286 Tolerance Chart

ISO Tolerances for Holes (ISO 286-2) ISO Tolerances for Holes (ISO 286-2) Nominal hole sizes (mm) over. 3. 6. 10. 18. 30.

ISO Standard Tolerance Table

Example for the DIN ISO 2768-2 tolerance table. This is just one example for linear tolerances for a 100 mm value. This is just one of the 8 defined ranges (30-120 mm).. Engineering tolerance is the permissible limit or limits of variation in: . a physical dimension;; a measured value or physical property of a material, manufactured object, system, or service;